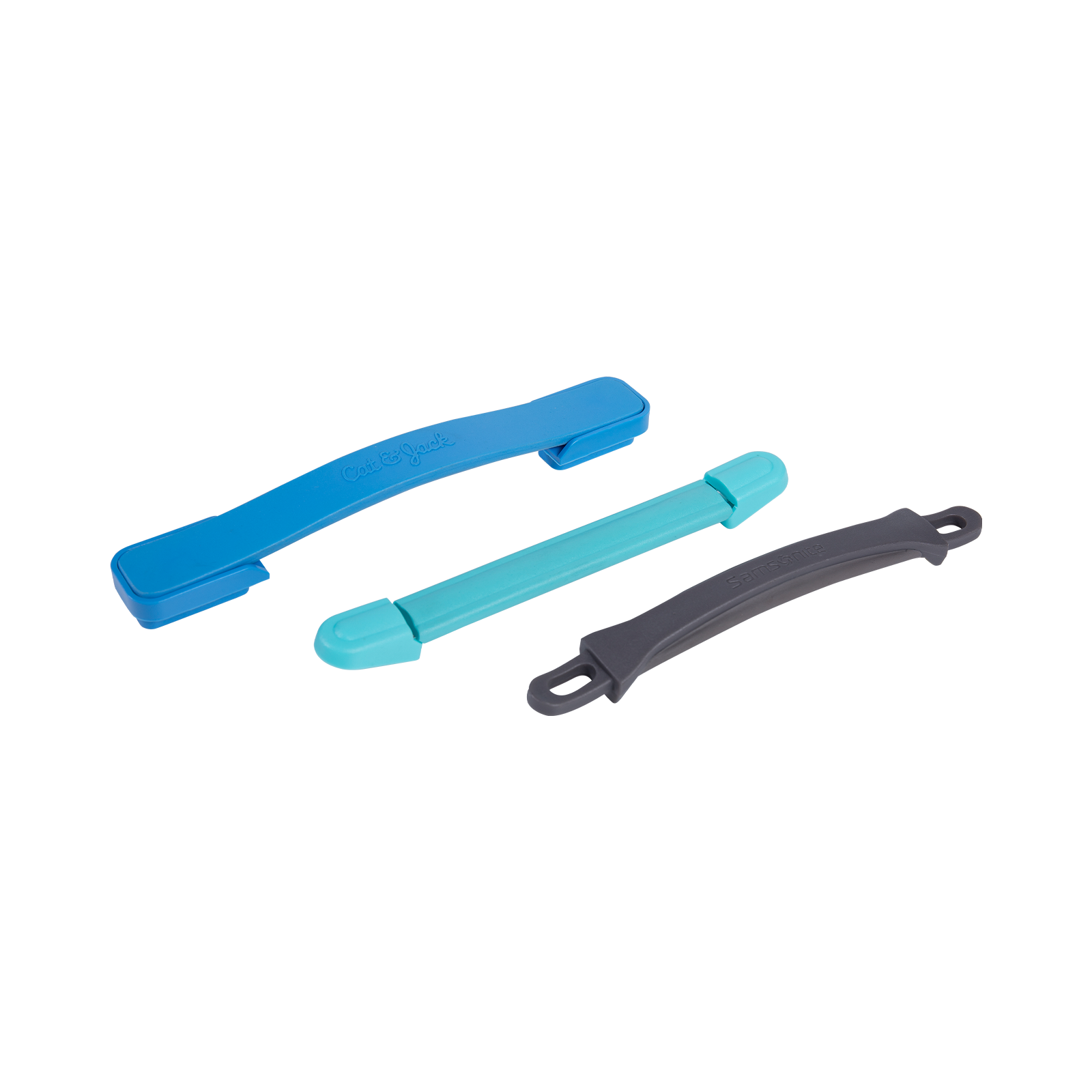

Testing and Evaluating the Load-Bearing Capacity of Plastic Luggage Handles

The testing and evaluation of the load-bearing capacity of plastic luggage handles follow specific standards and procedures to ensure their quality and safety. Below is a clear outline of the steps and key points involved in testing and evaluating the load-bearing capacity of plastic luggage handles:

Purpose of Testing

The purpose of testing and evaluating the load-bearing capacity of plastic luggage handles is to ensure that they can withstand the expected weight during actual use, thereby avoiding potential safety hazards such as breakage or deformation.

Testing Methods

Compression Test Method

Equipment: Use a compression testing machine to conduct the test.

Procedure:

Place the luggage handle on the testing platform.

Gradually apply compressive force until the predetermined testing conditions are met (such as specific time, displacement, or force value).

Record the maximum load-bearing capacity, deformation, and other relevant information during the test.

Tensile Test Method

Equipment: For some specially designed plastic luggage handles, a tensile testing machine can be used.

Procedure:

Secure the luggage handle in the tensile testing machine.

Gradually apply tensile force until the predetermined testing conditions are met.

Record the maximum load-bearing capacity, elongation, and other relevant information during the test.

Testing Standards

During testing and evaluation, national or international standards are usually referenced, such as GB/T (China National Standards) or ISO (International Organization for Standardization). These standards specify the specific methods, conditions, environment, and criteria for assessing test results.

Testing Conditions

Load Conditions: Set reasonable load conditions based on the design and usage requirements of the luggage. For example, for luggage intended for adult use, the handle's load-bearing capacity should generally not be less than a certain force value (e.g., 200N).

Testing Time: Set reasonable testing times based on the method used. For instance, in compression tests, a specific time or displacement may be set to observe the handle's deformation.

Testing Environment: Simulate actual usage conditions during testing, such as temperature and humidity, to more accurately evaluate the handle's performance in real-world scenarios.

Evaluation of Test Results

Maximum Load-Bearing Capacity: Assess whether the handle's maximum load-bearing capacity meets the design requirements and usage needs based on the test results.

Deformation: Observe the deformation of the handle during the test to evaluate its rigidity and stability.

Comparison with Standards: Compare the test results with standard values or design requirements to determine if the handle's performance is satisfactory.

Testing and evaluating the load-bearing capacity of plastic luggage handles involves adhering to specific standards and procedures, employing appropriate testing methods, setting reasonable testing conditions, and scientifically assessing the results. This process helps ensure the quality and safety of luggage handles, thereby enhancing the overall performance and longevity of the luggage.

Español

Español