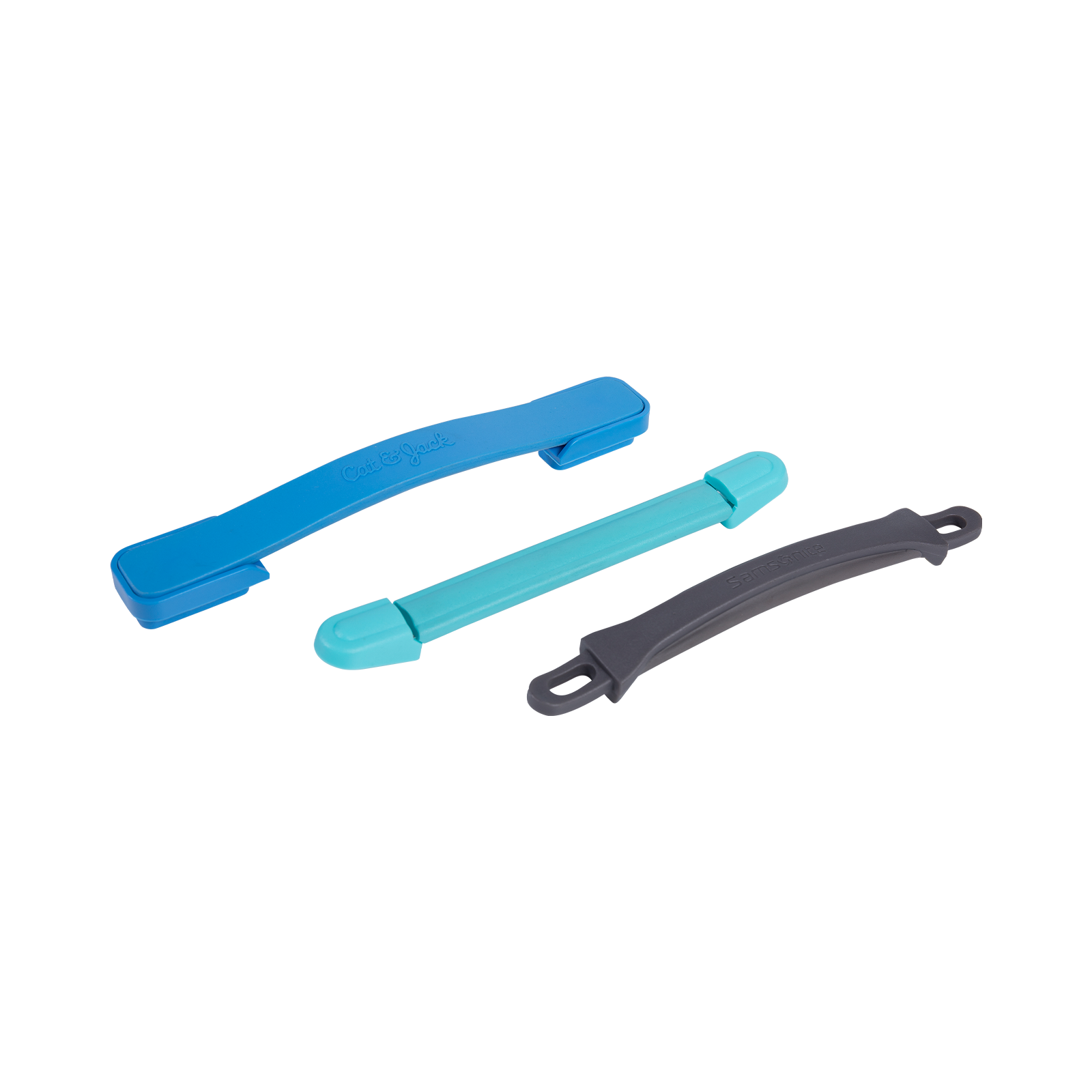

Luggage is an indispensable tool in daily life and travel, and the telescopic handle (Trolley Handle) in it is a key component of the luggage, which directly affects the comfort and convenience of use. Suitcase Trolley Handle Mold (luggage trolley handle mold) is the core equipment for producing high-quality trolley handles, which determines the structural strength, design accuracy and service life of the handle.

Suitcase Trolley Handle Mold is an industrial mold used to manufacture telescopic handles for luggage. Through injection molding, die casting and other processes, this mold can process plastic, aluminum alloy or stainless steel materials into handle components of specific size, shape and function. The design and manufacturing quality of the mold are directly related to the appearance, function and durability of the finished product.

The mold uses precision CNC processing, electrical discharge machining and other processes to ensure that the dimensions of each component are accurate, thereby ensuring the interchangeability and assembly efficiency of the handle assembly.

The mold supports the processing of a variety of materials such as plastic, aluminum alloy, stainless steel, etc., and can produce lightweight and durable trolley handles according to demand.

Mold design usually adopts a modular approach, which is convenient for quick replacement or adjustment to meet the customized needs of different customers.

By optimizing the flow channel design and cooling system, the mold can significantly shorten the molding cycle, improve production efficiency and reduce manufacturing costs.

According to the structural and functional requirements of the pull rod handle, 3D modeling is performed using CAD software to ensure that the design meets the mechanical and aesthetic requirements.

High-strength and wear-resistant mold steel (such as P20, 718H, etc.) is used as the mold material to improve the mold life and finished product accuracy.

Through processes such as CNC processing, wire cutting, heat treatment and surface polishing, the accuracy and smoothness of each part of the mold are ensured.

After the mold is processed, it is assembled, and its molding effect and production performance are verified by trial molds.

Qualified molds are installed on injection molding machines or die-casting machines for mass production of luggage pull rod handles.

The handles produced by high-quality molds are excellent in structural strength, appearance finish and operation smoothness, providing users with a better use experience.

The mold can achieve complex shapes and fine texture processing, so that the pull rod handle has a higher design aesthetics and brand recognition.

Through efficient mold design and material utilization optimization, enterprises can reduce unit production costs while ensuring quality.

With precise mold manufacturing, enterprises can quickly respond to market demand and launch more functional and personalized luggage handle products.

Application areas of Suitcase Trolley Handle Mold

Most travel luggage brands rely on molds to produce their handle components to ensure product performance and consistency.

For high-end luggage brands, molds support personalized customization to produce handles with brand characteristics.

In addition to the whole box handle, molds can also be used to produce handle parts, such as fixed seats, spring components, etc.

In the future, Suitcase Trolley Handle Mold will incorporate intelligent manufacturing technology, optimize mold structure through digital twins and AI algorithms, and improve design efficiency and finished product quality.

Adopt new wear-resistant materials and coating technology to extend mold life and reduce the cost of frequent replacement.

As the requirements for lightweight luggage increase, molds will further support the processing and application of high-strength, low-density materials, such as carbon fiber and new engineering plastics.

The concept of environmental protection promotes mold manufacturing to develop in the direction of low energy consumption and low emissions, and achieve sustainable development through recycling waste materials and optimizing processes.

As an important process tool in the luggage industry, Suitcase Trolley Handle Mold determines the quality and performance of the trolley handle. Its high precision, versatility and efficient production capacity not only improve the overall quality of the luggage, but also win market competitiveness for the company. With the advancement of technology and changes in market demand, mold manufacturing will continue to develop in the direction of intelligence, lightweight and green, injecting new vitality into the luggage industry.

Español

Español